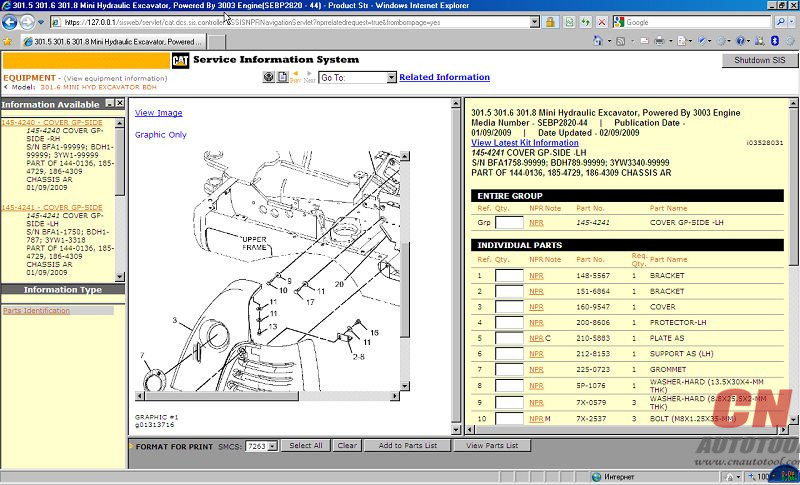

The PC-based service tools from Caterpillar provide the capability to access Electronic Control Modules (ECMs) from a personal computer. Many job-critical tasks can be performed with an electronic service tool. The user can display the status of a group of parameters (temperatures, pressures, etc.) simultaneously, view active and clear logged diagnostics, display the current configuration of an ECM and much more.

The service tool works with a communication adapter to allow connection to an CAT Caterpillar ET Diagnostic Interface. A graphical interface makes this software quick to learn and easy to use. A separate pull-down menu for each function enhances the ease of use The version and identification of the ECM is automatically retrieved and is displayed on a summary screen when the program is started. Diagnostic tests and calibrations can also be performed.

Caterpillar PC-based tools enable service technicians to reprogram ECMs, reconfigure control system parameters, fine tune performance or diagnose the root cause of a failure the first time. These powerful tools allow service personnel to display and analyze vital performance and health information from any system quickly and accurately. The service tool communicates with any system using ATA (J1708), J1939 or the CnAutotool.com proprietary data link networks.

The service tools provide information and features needed to help a technician diagnose problems and perform repairs and to customize and personalize the operation of a product. By allowing customers to design flexibility and configurability into a product, Caterpillar service tools stretch beyond the capabilities of preprogrammed ECMs or onboard display systems.

Display, graph and log status parameters. Retrieve prognostic data including histograms, engine totals for fuel used and miles traveled. View active diagnostics and clear logged diagnostics. View events where irregularities have occurred and have been logged by the ECM. Perform calibrations to enhance performance of the ECM. Customize the ECM with application-specific settings. Over 100 custom Diagnostic, Information and Service features including:

– 2D and 3D Histogram plotting capability (engine software support required). – Custom Status screen groups – Snapshots (Download and display snapshot data recorded by the ECM) – Configuration Aid that allows upload/download of same configuration to multiple control modules. Customized Service Tool Caterpillar Diagnostic Tool Options and service tool name. Major operating systems support (Microsoft Windows 95, 98, NT 4.0, 2000, ME, & XP) Perform customized diagnostic tests to identify harness problems, cylinder or component failures (Automatic Cylinder Cutout with cylinder to cylinder fueling comparison)

Features of Caterpillar CAT ET SIS :

Display graph and log status parameters.

Retrieve prognostic data including histograms, engine totals for fuel used and miles traveled.

View active diagnostics and clear logged diagnostics. View events where irregularities have occurred and have been logged by the ECM.

Perform calibrations to enhance performance of the ECM.

Customize the ECM with application-specific settings.

Over 100 custom Diagnostic, Information and Service features including:

2D and 3D Histogram plotting capability (engine software support required).

Custom Status screen groups

Snapshots (Download and display snapshot data recorded by the ECM)

Configuration Aid that allows upload/download of same configuration to multiple control modules

Customised Service Tool Options

Customized service tool name

Customized graphics for the splash screen and icons

Customized installation

Aftermarket differentiation, the tool for one customer does not work on the product of another customer.

Licensing options for customer management

Flash programming of the ECM(s)

Training demonstration allows familiarity with the toola s primary functions without connecting to ECM(s)

Major operating systems support (Microsoft Windows 95, 98, NT 4.0, 2000, ME, & XP)

Perform customized diagnostic tests to identify harness problems, cylinder or component failures (Automatic Cylinder Cutout with cylinder to cylinder fueling comparison