This is a Xtool A80 Bluetooth obd2 diagnostic tool test report with function explanation.

Tested on BMW X3 2015. Have a good success!

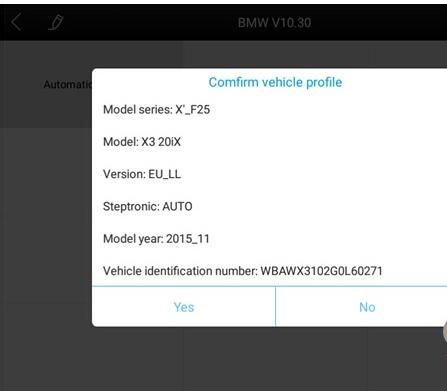

Car information:

Model series: X’_F25

Model: X3 20X

Version: EU_LL

Steptronic: AUTO

Model year: 2015_11

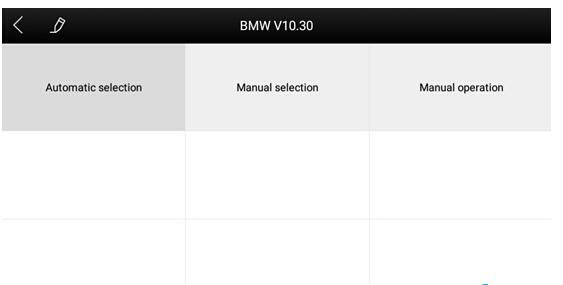

In Xtool A80 scanner:

select “BMW car”

– “Royal Car V8.70”

– “GX9”

– “Engine system”

– UMC engine system (UDS)

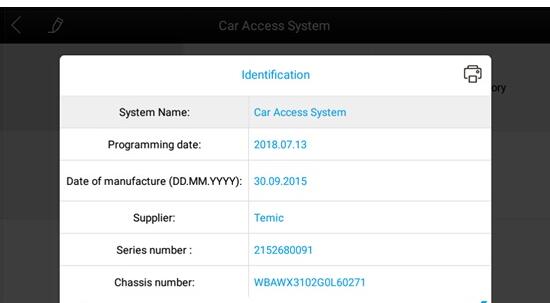

(1)This function is to read the ECU version information, in some of the electronic control displayed as “System identification” or “System Information” menu, the meaning is the same., It reads the ECU related software, hardware version and part number and other information. As shown in the following figure.

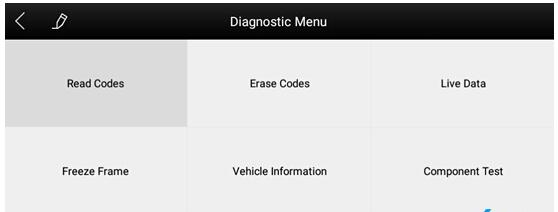

Select the “Read fault code” function to read the electronic control ECU stored in the fault code, read the fault code when the screen will display the read fault code and fault code definition

Tip: When the fault vehicle is detected, if the “system normal” or “No Trouble code” is displayed, the ECU does not store the relevant fault code or some fault phenomenon is not in the ECU monitoring range. It should be the mechanical system or circuit failure. And it is possible that the sensor in the range of signal deviation. This can be judged in the data flow function.

Clear DTCs with Xtool A80 scanner:

(1)Now select the “Clear Code” function to clear the ECU stored in the current and historical fault code memory, the implementation of this function will be the current fault code and the history of the fault code to clear all, clear the fault code before you need to confirm the failure code to record.

Model: X3 20X

Version: EU_LL

Steptronic: AUTO

Model year: 2015_11

(2)Click on “Yes” confirmation after clearing the fault code, such as normal communication will show “failure code cleanup success” or “fault code has been cleared”, usually after clearing the fault code and read the code to confirm the failure code is cleared.

Read live Data:

Click on “Save As Reference” function key, will save this model the current data stream of this system as a reference;

Click on the “Data Playback” function key to record the current data stream Dynamic Data, please go to the diagnostic report inside the data playback for review.

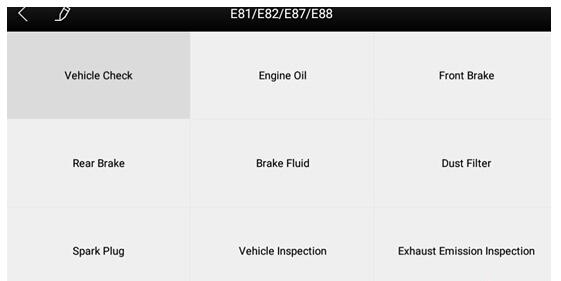

Special function:

The special functions of different vehicle systems will also be different.

Actuating components test:

Test conditions: Follow the instructions, for example: The engine is not running and the ignition switch is turned on. If the engine is started or the speed signal is recognized, the motion test diagnosis is interrupted.

(1)Return the menu to “dynamic diagnostic data” to see the “Action test” function menu, choose to display the system can be used to perform action test of the Actuator component menu.

Tip: The “Action test” function is a part of the system to perform functional testing of components, when performing this function, the diagnostic instrument will simulate the ECU signal to carry out the action of the component to determine whether the actuator or line is good.

(2)Return the menu to “dynamic diagnostic data” to see the “Action test” function menu and select the Actuator component menu that will display the system for action testing.